|

|

|

|

|

|

* Emulsification and Dispersion pressure of HOMOGENIZER according to the kind of dispersion quality

|

|

Homogeneous

Pressure

|

Food, Dairy Products |

Chemical Industry,Medicine,Cosmetics

|

|

100-250

(Kgf/㎠)

|

| (1)

Milk

(3) Soybean milk

(5)

Cooler

(7) Ice-Cream

(9)

Syrup

|

(2)

Fruit

Juice

(4) Yogurt

(6) Cream

(8) Ketchup

(10) Sauce

|

|

|

|

300-400

(Kgf/㎠)

|

| (11)

Milk

Fat

(13) Powdered

Milk

(15) Pudding

(17)

Mayonnaise

|

(12)

Chocolate

(14) Margarine

(16) Fodder

|

|

| (20)

Ink

(23) Fuel oil

(26)

Wax

(29) Perfurne

(32)

Wrapping Film

|

(21)

Shampoo

(24) Vitamin

(27) Lubricant

(30) Resin

|

(22)

Soap

(25) Toothpaste

(28)

Paint

(31) Paper

Additive

|

|

|

600-1000

(Kgf/㎠)

|

| (18)

Liquid

food

|

(19)

Yeast

|

|

| (33)

Medical

Supplies

(36) Silicon

|

(34)

Cosmetics

(37) Emulsifier

|

(35)

Dyestuff

(38) Resin

|

|

|

|

* Homogeneous Notion and Moving Principle

|

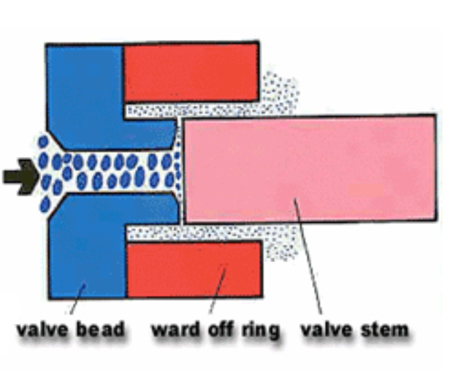

The homogenization process is a valve part that can be adjusted in intervals. When a high pressure fluid is introduced into the valve part, the fluid material carries out the car motion in the homogenization valve. In other words, high pressure (up to 1,000 Kgf / cm2) fluid generated by the Flanger action will pass between small gaps in the VALVE BEAD, WARD OFF RING, and VALVE STEM at high speeds of 200 to 300 m / s.

As the high pressure fluid passes through the excitation, a sudden pressure drop occurs, flow cavitation, turbulence and transfer force are formed, and this phenomenon continues to be maintained, so that the levitation force is reduced by breaking into fine particles of 0.3 micron or smaller , The liquid component is formed into a perfectly uniform particle shape.

This finely dispersed lipstick or lipstick (particle size) is stabilized in a state that it does not float because the friction becomes stronger than buoyancy, and the appearance of the product is excellent. If the product is a food, it will maximize the taste and quality effect. If it is an organic chemical substance, it will make the particle size of the dispersion even, and it will make the self dispersion power and storage stability excellent.

This machine principle plays a pivotal role in the production line of each manufacturing or oil painting field.

|

|

|

|

* Particle Size Observation

|

|

* Flow Rate Condition according to Application Pressure

|

|

TYPE

|

Flow Rate

|

Pressure(MPa)

|

Power

(kW)

|

|

100

|

80

|

60

|

40

|

30

|

25

|

20

|

15

|

|

Laboratory

|

ℓ/h

|

40

|

|

60

|

|

120

|

|

|

|

2.2

|

|

Production

|

100

|

|

120

|

|

250

|

|

|

|

4

|

|

|

|

400

|

600

|

800

|

1000

|

|

|

7.5

|

|

300

|

400

|

500

|

750

|

1000

|

1500

|

1500

|

|

11

|

|

|

|

|

1000

|

1500

|

2000

|

2500

|

|

15

|

|

600

|

800

|

1000

|

1500

|

2000

|

2500

|

3000

|

|

22

|

|

800

|

1000

|

1500

|

2000

|

3000

|

4000

|

|

|

30

|

|

1200

|

1500

|

2000

|

3000

|

4000

|

5000

|

6000

|

8000

|

45/37

|

|

1600

|

2000

|

3000

|

4500

|

6000

|

7000

|

9000

|

10000

|

55

|

|

2400

|

3000

|

4000

|

6000

|

8000

|

10000

|

12000

|

15000

|

75

|

|

|

|

5000

|

7500

|

10000

|

12000

|

15000

|

18000

|

90

|

|

|

|

6000

|

9000

|

12000

|

14000

|

18000

|

22000

|

110

|

|

|

|

7000

|

10000

|

14000

|

16000

|

20000

|

25000

|

132

|

|

|

|

8000

|

12000

|

16000

|

20000

|

24000

|

30000

|

160

|

|

| |

* All of our products are carefully selected based on our long-term R & D and know-how.

* We have a variety of solutions for our customers, and we are constantly researching and developing for the best results. |

|

|

|